Pillar specializes in the design and fabrication of metal and plastic parts, tooling, and custom machined items. On every project, for every customer, we methodically apply our speed, knowledge, quality, and flexibility to ensure the optimal final product.

Metal and Plastic Parts Fabrication

Metal and Plastic Parts

Stamping Metal Parts

Stamping is the process of placing flat sheet metal in either blank or coil form into a stamping press where a tool and die surface forms the metal into a net shape. Stamping includes a variety of sheet-metal forming manufacturing processes, such as punching using a machine press or stamping press, blanking, embossing, bending, flanging, and coining.

Casting Metal Parts

Casting is a process in which a liquid metal is somehow delivered into a mold that contains a hollow cavity of the intended shape. The metal and mold are then cooled, and the metal part (the casting) is extracted. Casting is most often used for making complex shapes that would be difficult or uneconomical to make by other methods.

Machining

Machining is any of various processes in which a piece of raw material is cut into a desired final shape and size by a controlled material-removal process.

Plastic Parts

When designing a plastic product, you are faced with many requirements: time-to-market pressure, budget limits, material selection, “moldability”, tooling expense, minimal engineering changes and tool qualification time. Pillar works with you to find the best solution for your project, balancing your budget, timeline and logistical requirements.

Plastic Tooling

Injection molding tools are available in single, family and multi-cavity mold configurations. We’ll work closely with you to evaluate options and modify part designs to make precision injection molds that produce both functional and economically moldable finished parts.

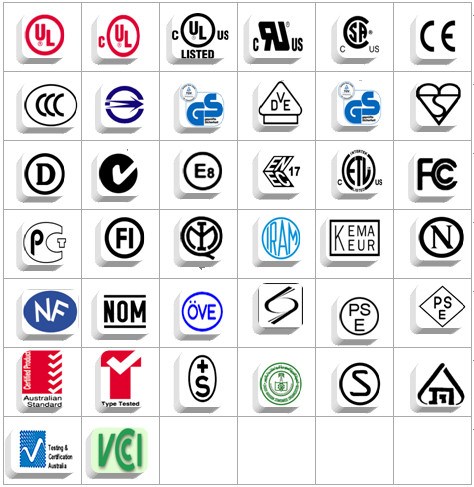

Safety Approval Standards.

We can meet a wide range of safety standards, specifications and certifications. Let us know the requirements for your project and we’ll ensure that it meets the necessary standards.